Zero Point System Product Features

1. Why do we need the Zero Point System?

The most valuable is the ability of the personnel,

Make complex things easy with suitable equipment,

simple things to do easily,

achieve maximum resource efficiency.

1-1. Make line change quickly

● It takes a lot of tools to change the line, disassemble and assemble the fixture, and the recalibration and replacement of the fixture requires professionals and sufficient time. After changing the line, a small amount of trial production is required to confirm the production items. After changing the line, a lot of tools must be returned. These things can make the zero point system simplify the cumbersome procedures.

1-2. Less non-machining time

● The loading and unloading time is difficult to predict, and it will be different with the material, fixture or personnel factors, so the zero point system can optimize the material change time.

1-3. Fixture interface all in one

● The zero point system can make the tooling interface of each machine as simple as placing the fixture or workpiece, and all the steps will not vary from person to person, and it also allows the production management personnel to quickly adjust the available machines to schedule production.

2. Where is the competitive advantage of our products?

The advantage comes from a pragmatic spirit,

the most suitable product can show the competitive advantage of the industry

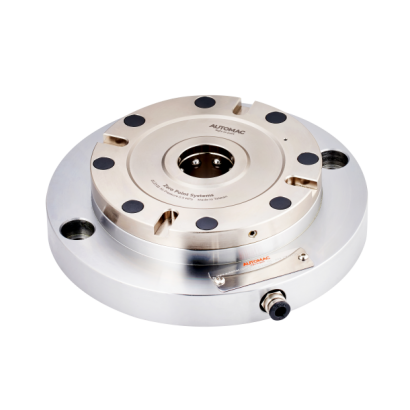

2-1. High-strength alloy steel for the body

● The main body is made of special alloy steel and special coating. The tensile strength exceeds 830MPa (85kgf/mm²), and its strength is more than 1.5 times that of stainless steel. Whether it is milling or drilling, it improves the machine's greater performance.

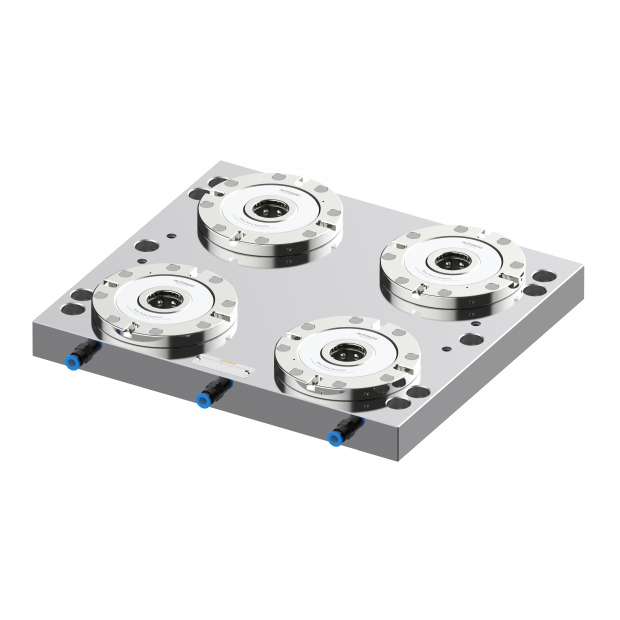

2-2. Modular Functional Features

● Zero point system - HSK same-level positioning taper, with high strength and high reliability characteristics.

● Quick clamping - bearing-grade high-strength steel balls for durability and reliability.

● Precision cross keyway - when used in a single seat, it can prevent the upper workpiece from rotating, and the cross keyway can also be used to convert angle processing.

● Steel ball anti-dust - use the principle of air curtain positive pressure to reduce the probability of dirt entering the body.

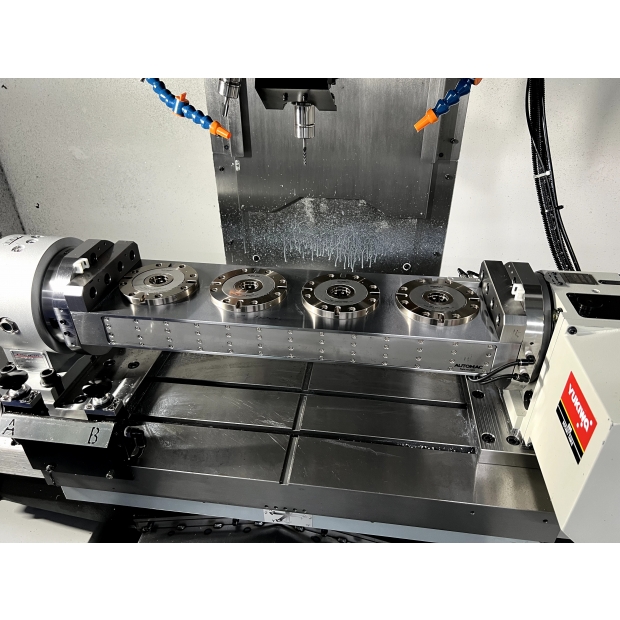

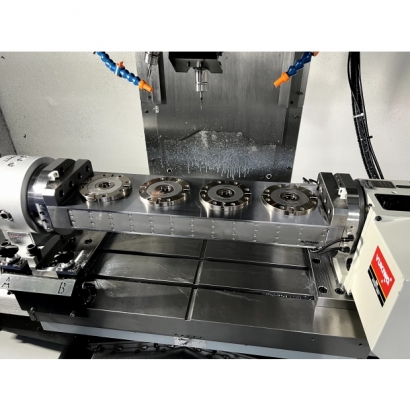

● Vertical and horizontal use - can be used horizontally or vertically, no need to adjust the internal structure in the factory, and can be applied in different situations.

2-3. Capacity Matching

● Non-mass production - collocation with the zero point system to quickly change the clamping fixture or collocate with different processing machines to change the manufacturing process.

● Mass production - use with the zero point system to change the plate or use it with the robot arm for loading and unloading.

2-4. High Strength Modular Pull Bolt

● The pull bolt body is made of special alloy steel with a tensile strength exceeding 830MPa (85kgf/mm²). Using the same pull bolt with the same specification makes management easier.

3. What is the difference between the zero point system and traditional clamping?

People are the core of an enterprise, so that the ability and benefits of personnel can be maximized.

Zero Point System

Traditional Tooling

Line change time

short

long

Personnel experience

short time

trainning experience

Production capacity

high

general

Man-machine ratio

many

general

Tooling interface

standardization

non- standardization

Replacement tool

none

many

Application method

logical

rely on experience

4. What can we get with the zero point system?

Streamlining complexity, shaping a brighter tomorrow. Your time, our focus.

Easier Management

Simplify many procedures and make everything easier.

More Flexible Process Options

Tooling interface is standardized and can be used with different machines.

Improve Staff Stability

Let all variables be controlled by equipment to reduce human factors.

5. What can Automac Smartauto assist you with?

Zero point system integration NO.1

Appropriate System Integration Solution

Pneumatic system, turn plane or automation can all be integrated.

Instant Assessment Planning Services

Free assistance to evaluate the planning, and get whether the tool or fixture interferes in time.

Safe whole plant installation service

Installation test run and training are completed at one time.

Zero Point System Product Features

Zero Point System Product Features 3-Axis Advanced Type

3-Axis Advanced Type 3-Axis Advanced Type

3-Axis Advanced Type 4-Axis Standard Type

4-Axis Standard Type 4-Axis Advanced Type

4-Axis Advanced Type 5-Axis Standard Type

5-Axis Standard Type 5-Axis Advanced Type

5-Axis Advanced Type Quick Point System

Quick Point System Production machine with Zero-Point clamping system

Production machine with Zero-Point clamping system